Hi,

I thought I might share pictures of some work in progress I am currently working on. As you might have read in the other sections of this forum, I particulary like the F/W 2011 edition paneled jacket from Gareth Pugh.

Make or Buy?

Unfortunately, this style is available for women's only, which means that the sizes produced are up to an Italian size 46. If you search online, you will find a jacket at lindestore in size 44 (IT) only, which is way too small for me anyway.

In addition, I had mailed Gareth Pugh's press contact a few months back, and back then, the official answer was that the jacket would be produced with Neoprene and matte lamb leather.

The current version which is sold is made of PVC and jersey. I don't mind the jersey, but I don't like PVC that much. Lastly, the quality control is not the best, as the topstitching leaves mixed impressions:

While looking closer at various pictures of the item that is for sale, I even discovered a couple of seams that were even further off.

Gareth, if you are reading this:

- Please produce your jackets in a size 48 also

- spend some more resources on quality control

A new project is born: Gathering the ingredients

So I decided to sew this jacket by myself.

I bought Neoprene fabric while being on a business trip in London back in April, and searched for a very long time for the appropriate leather.

The original (maybe the runway) jacket had matte lamb leather, so I tried to find this type of leather. That's not as easy as one would guess, as even the leathers that are sold as "matte" do still reflect very much light.

In total, I contacted 8 online stores and got over 20 samples of leather, all that should have been "matte". Especially in the automobile industry, matte leathers are used for seats, whereas the matte leathers that you find in clothing are still too shiny.

I ended up with BMW nappa leather. As the dealer doesn't sell smaller sizes, I ordered a full animal's skin, which is around 5.48 square meter (which now occupies most of my living room floor not to get further bends ).

).

I also found a store that sells the golden metal zippers in custom lengths, so I've got the exact size of the zipper that I need for both the front opening + the zippers at the sleeves.

Appliqué analysis

I developed the basic pattern via a jacket pattern that I still had, and adjusted the fit, so it would fit very closely - closer than a slim fit shirt would fit.

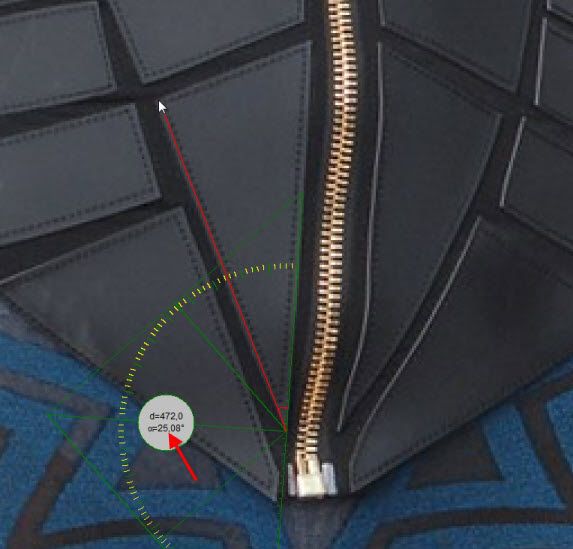

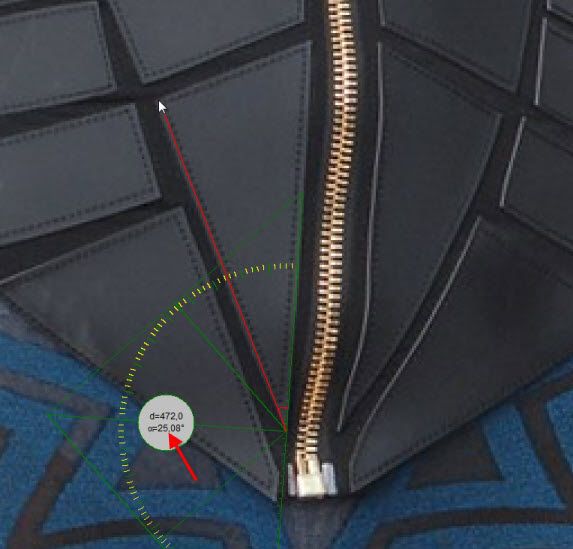

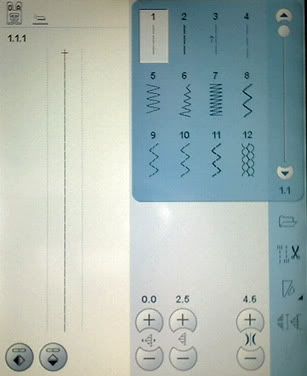

Then I started analyzing the geometric proportions of the various appliques on the jacket, using a tool that allows to measure angles on one's computer screen:

(here you can see an angle of 25°)

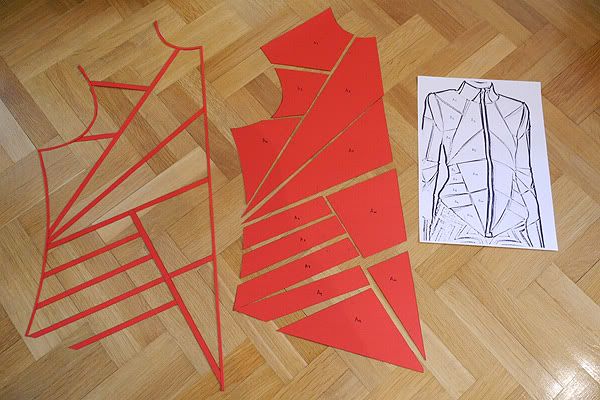

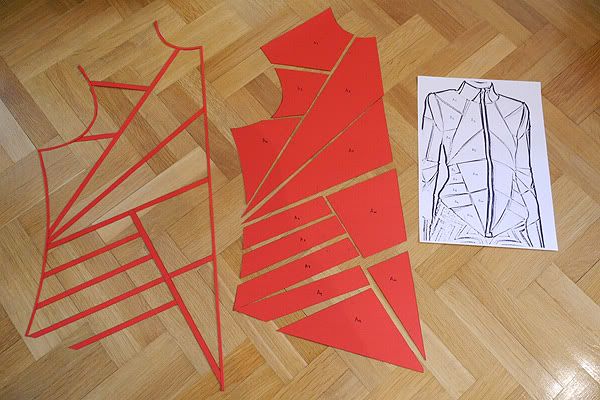

I also analysed the proportions of the size of the pieces to each other and adjusted these for the bigger size and different pattern that I would be using. I copied my pattern onto cardboard, drew the applique pattern onto it and cut out the single pieces:

(same applies for the back and the sleeves)

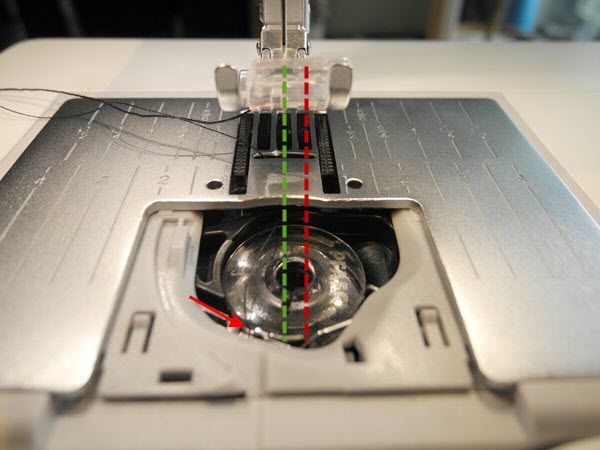

Today, I started cutting out the appliqué items from the leather, glueing them onto the neoprene with a temporary spray adhesive (so they wouldn't move while putting the topstitching on) that will dissolve in the next 5 days without residue, and finally did the topstitching on one front panel.

Here's how it looks so far:

It's a lot of work, especially cutting the leather. I will probably stop working on the jacket for today, and continue next weekend.

I can probably do one item (other front, back, sleeve 1, sleeve 2, collar, lining, finishing up) per weekend, so it might still take several weeks to finish. Still... I was so excited to finally see things coming together (after spending the previous weekends on gathering the materials and adjusting the underlying pattern) that I just needed to share this little bit... :-)

Cheers,

marc

I thought I might share pictures of some work in progress I am currently working on. As you might have read in the other sections of this forum, I particulary like the F/W 2011 edition paneled jacket from Gareth Pugh.

Make or Buy?

Unfortunately, this style is available for women's only, which means that the sizes produced are up to an Italian size 46. If you search online, you will find a jacket at lindestore in size 44 (IT) only, which is way too small for me anyway.

In addition, I had mailed Gareth Pugh's press contact a few months back, and back then, the official answer was that the jacket would be produced with Neoprene and matte lamb leather.

The current version which is sold is made of PVC and jersey. I don't mind the jersey, but I don't like PVC that much. Lastly, the quality control is not the best, as the topstitching leaves mixed impressions:

While looking closer at various pictures of the item that is for sale, I even discovered a couple of seams that were even further off.

Gareth, if you are reading this:

- Please produce your jackets in a size 48 also

- spend some more resources on quality control

A new project is born: Gathering the ingredients

So I decided to sew this jacket by myself.

I bought Neoprene fabric while being on a business trip in London back in April, and searched for a very long time for the appropriate leather.

The original (maybe the runway) jacket had matte lamb leather, so I tried to find this type of leather. That's not as easy as one would guess, as even the leathers that are sold as "matte" do still reflect very much light.

In total, I contacted 8 online stores and got over 20 samples of leather, all that should have been "matte". Especially in the automobile industry, matte leathers are used for seats, whereas the matte leathers that you find in clothing are still too shiny.

I ended up with BMW nappa leather. As the dealer doesn't sell smaller sizes, I ordered a full animal's skin, which is around 5.48 square meter (which now occupies most of my living room floor not to get further bends

).

).

I also found a store that sells the golden metal zippers in custom lengths, so I've got the exact size of the zipper that I need for both the front opening + the zippers at the sleeves.

Appliqué analysis

I developed the basic pattern via a jacket pattern that I still had, and adjusted the fit, so it would fit very closely - closer than a slim fit shirt would fit.

Then I started analyzing the geometric proportions of the various appliques on the jacket, using a tool that allows to measure angles on one's computer screen:

(here you can see an angle of 25°)

I also analysed the proportions of the size of the pieces to each other and adjusted these for the bigger size and different pattern that I would be using. I copied my pattern onto cardboard, drew the applique pattern onto it and cut out the single pieces:

(same applies for the back and the sleeves)

Today, I started cutting out the appliqué items from the leather, glueing them onto the neoprene with a temporary spray adhesive (so they wouldn't move while putting the topstitching on) that will dissolve in the next 5 days without residue, and finally did the topstitching on one front panel.

Here's how it looks so far:

It's a lot of work, especially cutting the leather. I will probably stop working on the jacket for today, and continue next weekend.

I can probably do one item (other front, back, sleeve 1, sleeve 2, collar, lining, finishing up) per weekend, so it might still take several weeks to finish. Still... I was so excited to finally see things coming together (after spending the previous weekends on gathering the materials and adjusting the underlying pattern) that I just needed to share this little bit... :-)

Cheers,

marc

...

...

Comment