'wait' by Dario Ruggiero now on IG

.

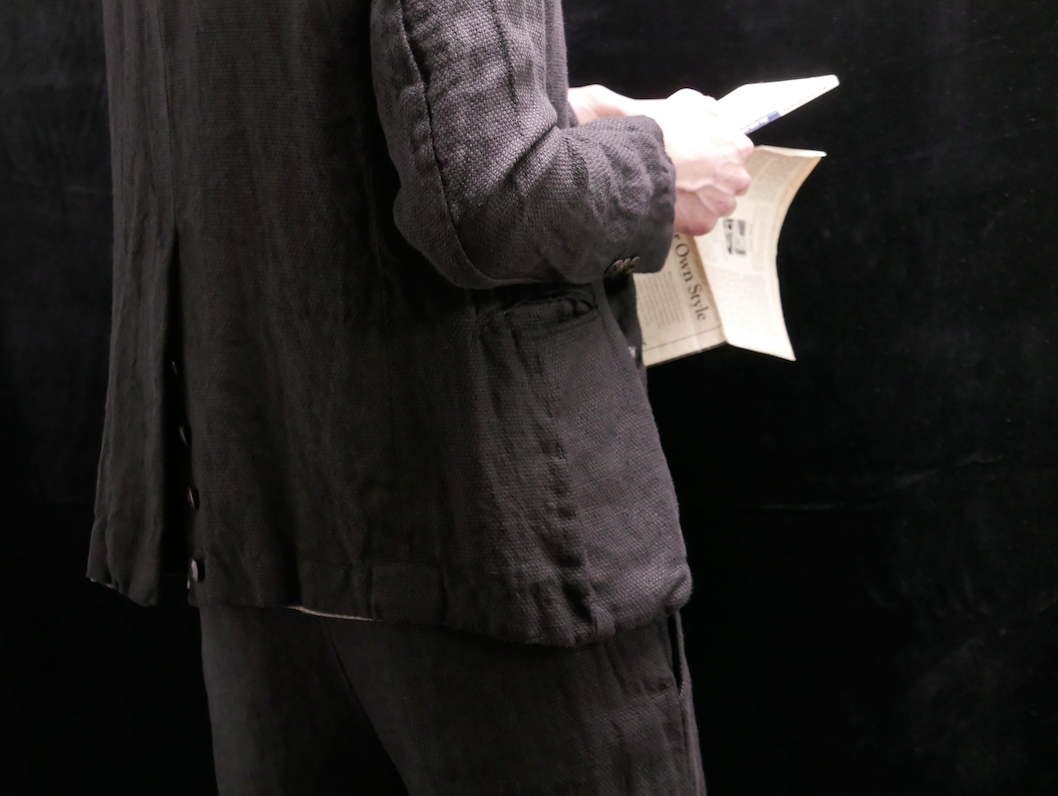

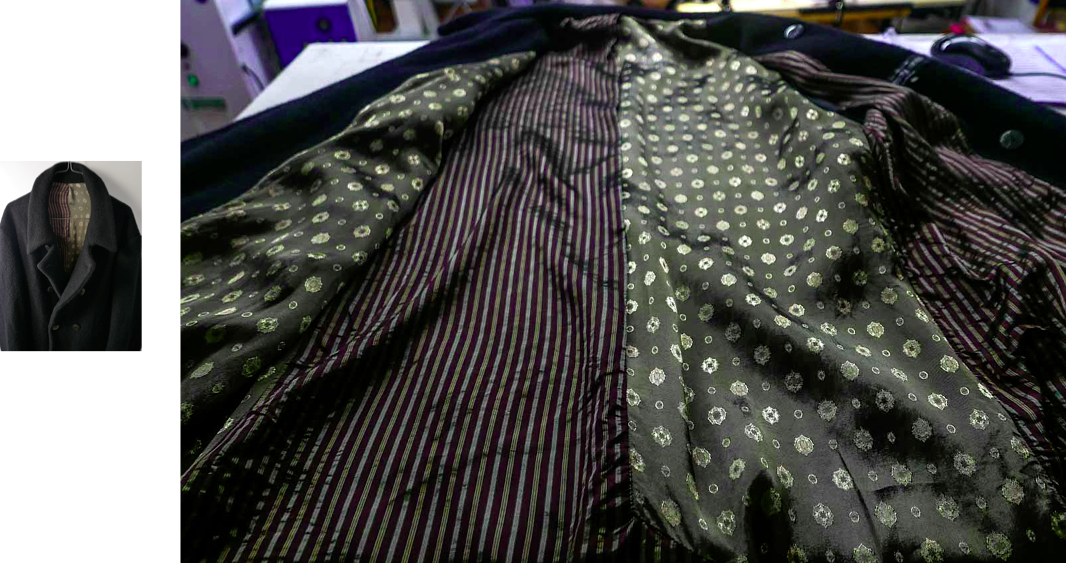

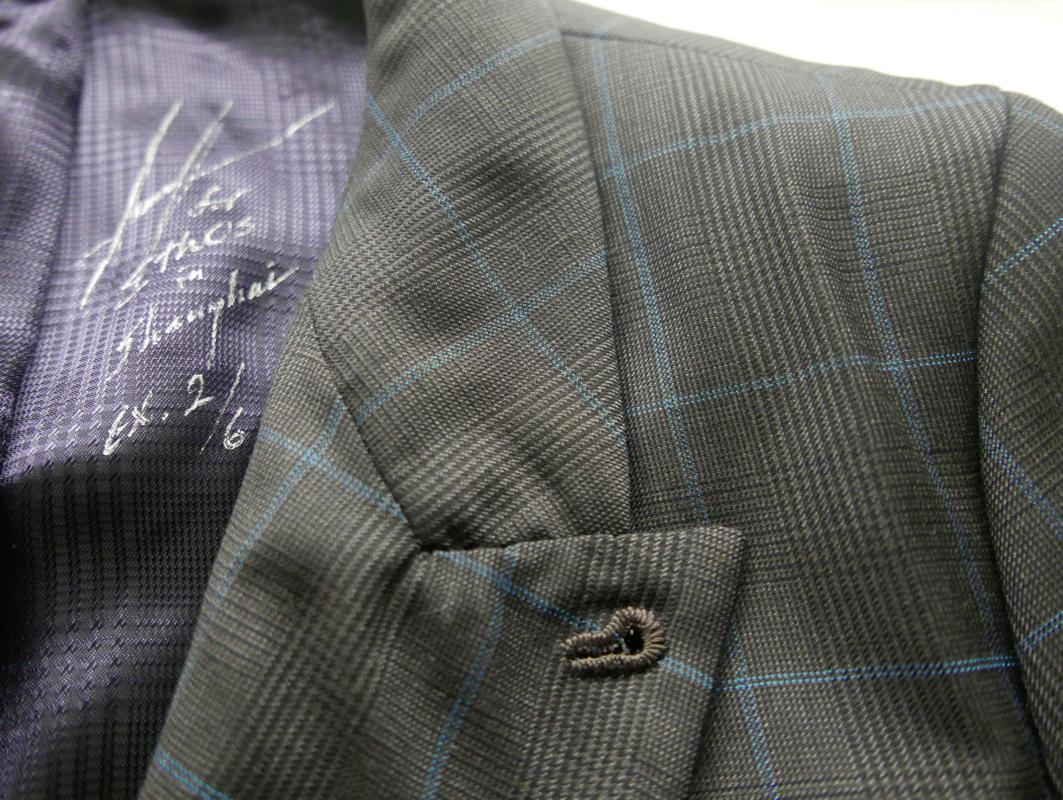

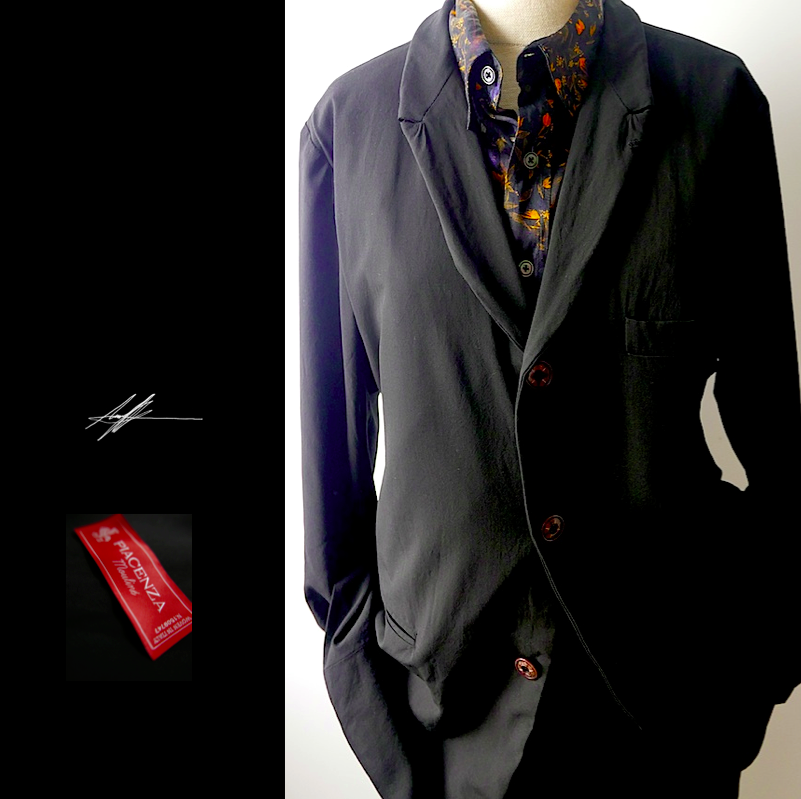

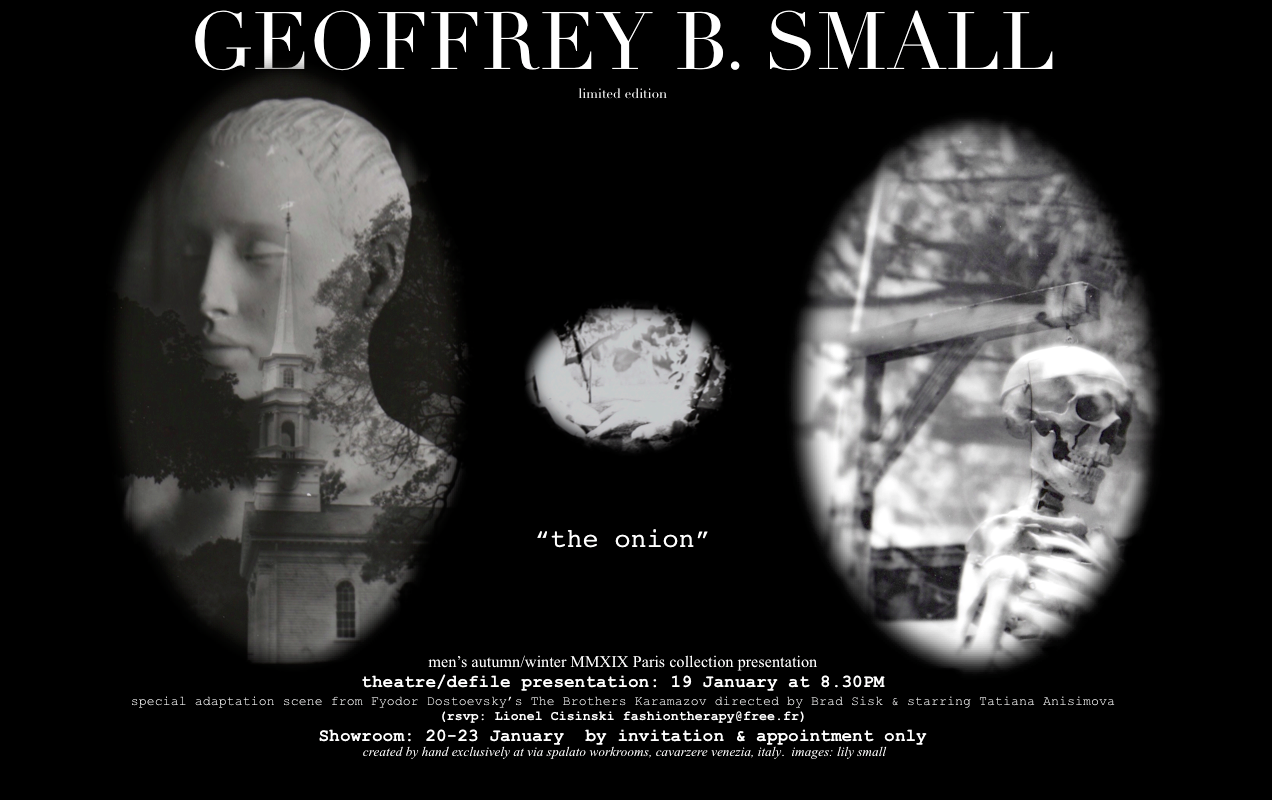

Pre-show rehearsal and backstage images of Diana Akimova in Fratelli Piacenza's new Mouline' super 130's incredibly lightweight summer wool handmade bomber jacket ensemble developed by Nicholas Giannelli and Laurine da Boville wearing the new super-shouldered handmade long coat in exquisitely textured superlux cotton woven entirely by hand on 18th century wooden handlooms at Badoere di Morgano by Tessitura La Colombina developed by Lois Dionisio- part of Dario Ruggiero’s beautiful photo essay of 'wait’ in Paris now up exclusively on our official instagram page here.

We also eagerly await the release here on SZ of Matthew Reeves editorial story, who also photographed the collection backstage before the show in Paris. More coverage and news on the record-breaking collection soon. Cheers, Geoffrey & the team

photos this post © Dario Ruggiero, all rights reserved. www.darioruggiero.com

Visit GBS on instagram https://www.instagram.com/geoffreybsmall

.

.

Pre-show rehearsal and backstage images of Diana Akimova in Fratelli Piacenza's new Mouline' super 130's incredibly lightweight summer wool handmade bomber jacket ensemble developed by Nicholas Giannelli and Laurine da Boville wearing the new super-shouldered handmade long coat in exquisitely textured superlux cotton woven entirely by hand on 18th century wooden handlooms at Badoere di Morgano by Tessitura La Colombina developed by Lois Dionisio- part of Dario Ruggiero’s beautiful photo essay of 'wait’ in Paris now up exclusively on our official instagram page here.

We also eagerly await the release here on SZ of Matthew Reeves editorial story, who also photographed the collection backstage before the show in Paris. More coverage and news on the record-breaking collection soon. Cheers, Geoffrey & the team

photos this post © Dario Ruggiero, all rights reserved. www.darioruggiero.com

Visit GBS on instagram https://www.instagram.com/geoffreybsmall

.

Comment