Originally posted by Lohikaarme

View Post

Announcement

Collapse

No announcement yet.

Geoffrey B. Small

Collapse

X

-

I believe Geoffrey is very much in favor of tailoring. The garments should be suited to the wearer and forming a relationship with your local tailor is important. Any tailor that does more than simple alterations should be able to sew additional or replacement buttonholes by hand but it'll cost you.

-

-

it should not be more than 5 dollars to open a hole by machine , but by hand it would vary really. Also button placement is tricky on pre made garments so it is case by case basis, someone else can chime in on this too though just my thoughts, but it's like how GBS said sometimes it's "seemly impossible " for some fabricsOriginally posted by yubbermax View PostI believe Geoffrey is very much in favor of tailoring. The garments should be suited to the wearer and forming a relationship with your local tailor is important. Any tailor that does more than simple alterations should be able to sew additional or replacement buttonholes by hand but it'll cost you.Originally posted by unwashedTry to use a phone camera in broad daylight or use a proper camera.Originally posted by AhimsaI've found it extremely pleasant and enthralling over repeated whiffs so I would highly recommend.

Comment

-

-

GBS thank you for the information! The images you provided were very helpful. :)

I have decided on purchasing the two LMS07 Super 120's organic cotton shirts (dark and white) they have in my size (48) for the time being. I will save up some money in the mean time for next seasons collection where I hope to purchase a pair of trousers and perhaps even a jacket to compliment the aesthetics and overall look. I thought it better to purchase two of your pieces rather than one.

I would also just like some clarification on the current AW15 menswear collection. Is it only being stocked exclusively at Hotoveli? I know Eth0s have a few SS15 pieces, but they have only small sizes left in stock (I only recently learnt about your work so had I known earlier I would have purchased a few more in my size), and I have been trying to contact Hostem in the UK without any response.

In regards to SS16, I have received a pre order list of select items from Cruvoir, but are there other stores that will stock SS16? I am eager not to miss out this time around.

Comment

-

-

Dear Mojo1990,

Thanks for your post and purchases with Hotoveli.

To answer as quickly as possible, our AW15 men's collection "Witness"

is available at the following dealers:

Hotoveli New York

Hostem London

Persuade Bilbao*

Darklands Berlin*

Eth0s, Shanghai*

Surrender, Singapore*

Arts&Science, Aoyama (Tokyo)

Johnbull private labo Harajuku (Tokyo)*

AL Select, Kichijoji (Tokyo)*

Souterrain, Roppongi (Tokyo)

Cathedral, Osaka*

Provogue, Nagoya*

Restrict, Utsunomiya*

Liberte, Kobe*

Johnbull private lab, Okayama

Farenah, Sofia

* deliveries now or still arriving

SS2016 men's "Radicalissimmo" (to be confirmed)

Note that SS2016 has set record orders and currently exceeds our current projected production capacity. We are reviewing the entire season's order requests and our current production operations and staffing at the moment and are unable to state exactly if all of the below will have the collection although they have all placed standing orders for it:

Hotoveli New York

Hostem London

Persuade Bilbao

Darklands Berlin

Eth0s, Shanghai

Surrender, Singapore

Secret Service, Taipei

Arts&Science, Aoyama (Tokyo)

Super A Market, Aoyama (Tokyo)

Land of Tomorrow, Marunouchi (Tokyo)

AL Select, Kichijoji (Tokyo)

Gallem, Daikanyama (Tokyo)

Souterrain, Roppongi (Tokyo)

Cathedral, Osaka

Provogue, Nagoya

Restrict, Utsunomiya

Liberte, Kobe

Hues, Fukuoka

Farenah, Sofia

IF New York

Cruvoir, Los Angeles

Hope this is helpful.

p.s. I have just sent you a PM regarding your other questions.

For Lohikaarme, Yubbermax, and Trigger Discipline...

Thanks also for each of your posts. Regarding alterations capabilities on our pieces, I need more time to reply in depth. But for the moment I can state that very few, if any, other designer collections in the world are designed to be more suitable for alterations capability than ours. For an explanation in more detail, I will post more later on this… sorry gotta work right now on a delivery.

Cheers and thanks to everyone,

Geoffrey

.

Comment

-

-

Thank you

Hi, Geoffrey

I just tried on the new GJ04 jacket from eth0s Shanghai. It was everything that I've dreamed of. The fabric is cashmere and silk, but it kept me warm surprisingly well during this cold day. I absolutely love the design of linings too. Here, I just have one humble question: I very much admire your courage and talent to create clothes on better standards every season. Therefore, has the GJ04, or other classic jackets of yours changed over time? Or do you keep the same method in making them?

Thanks again for the inspiration and great work!

Have a wonderful day.

Jay

Comment

-

-

Fashion designer Vs Clothes maker

Reading the interesting discussion about Geoffrey B. Small and Paul Harnden.

I definitely agree that Harnden is no match of Geoffrey in terms of fashion design, but some of his clothes are good product (I am not talking about quality, but atmosphere that the clothes give off).

Its a difference in philosophy. One goes to try and make something new and revolutionary, the other tries to perfect a certain style. Anyway I thought the argument was too one sided against PH so I chipped in. (I know how everyone is pissed with him cause of his business strategy)

I dont know what PH is thinking but I wish it was something close to Nigel Cabourn.

A quote from Nigel Cabourn....

I don’t class myself as a ‘fashion designer’ as I don’t follow fashion. Everything I design comes from either a moment in history, an inspirational person or a vintage garment.

...which have on the whole, been created not by fashion designers but by technicians and scientists.

For me product comes first....At the end of the day my aim with each collection or collaboration is to create timeless styles that have the quality to last, get better with age and wear and that are still relevant in years to come. Clothing that people can wear for a lifetime then pass down to their children.

– Nigel Cabourn

By the way I personally respect a band that changes over time far more than one that makes the same music album after album.

Comment

-

-

I really don't see the need to compare the two at all.Fashion is a form of ugliness so intolerable that we have to alter it every six months - Oscar Wilde

StyleZeitgeist Magazine

Comment

-

-

"Fashion designer vs Clothes maker" & Our View on Alterations

.

N.B. Although I had been preparing this reply several weeks ago to both Lokihaarme and zero25mg, as a result of the recent events last weekend, I have refrained from posting it until now. Our sincerest condolences, thoughts and prayers go out to everyone we know and/or work with in Paris and all of their families and friends, as well of course to all of the victims of the tragic events in the city and beyond.

Thank you Faust. I agree. Dear zero25mg, thanks for your post and comments. I understand you are a new member and this may have been one of your first posts on SZ, so there is much to learn…

First of all, I must really take issue with your title "fashion designer vs. clothes maker." I am a clothes maker, and have been one for almost 40 years. A real one. I can draw a design freehand, make and draft its pattern on paper without CAD, grade and modify it as needed, cut its cloth by hand with scissor single-ply or multiple, sew it together on both machine and by hand as necessary, dye and treat its cloth by machine or hand also as required, and fully hand press and finish it using board and iron or whatever equipment is available. And I am racing with every second, every moment and every penny I have left on this planet to try to teach a new generation of human beings in this world to be able to do the same and carry forward this Art before it is too late. Our track record on this kind of thing, both for myself personally, and my firm and the people I work with, as such, is unmatched. You really need to do more homework on the subject of Geoffrey B. Small and clothes-making.

And then there's that reference to Nigel who? You have got to be kidding... That name or rather, "brand" with its phony website quote does not belong anywhere here in our thread, or in my opinion, on SZ period. It is a pure, commercial, typical "garmento" type play and belongs as far away from us, (and that includes both Paul Harnden and Geoffrey B. Small) as possible. I mean some guy (or ad copy-writer) claims to spend his life buying (oh sorry, "collecting" is the term used) old clothes, tries to get factories to copy them as best as they can… and then calls himself an "important designer" using a concept totally ripped off from others?

For us, the word is "merchandiser." At best.

And those types are a dime a dozen, and are everywhere these days--overrunning the business with their bullshit and their hype. Hedi and Tom Ford perfected the game and now what's his name Kanyuck? is up to the same crap with a line called Cheesy season 1 or whatever it's called. 3000 dollar plastic army parkas made in China… right, FU. And that Instagram poster with the fur and the cupcake shop is another one. The sooner these media schmoozers, fakers and bums get out of the business the better in my opinion. Nothing has damaged the creative capacity and the opportunity for noble young people to survive, grow, and prosper in this industry more than the swarm of what the great Take Hirakawa first-labeled "Fashion DJ's" and the corporate parasites, accountants and media that use them, feed off of them, and support them. And you can throw the lot at Balmain and H&M into that trashbin as well.

But since its beginning, thanks to people like Faust, Lowrey, Fuuma, BSR, gallia, mrbeuys, shucks, zamb, surver, chinorlz, et al.,... and a long line, too many to mention, of all those who have participated, and forged it over the years, SZ has been about something a little more substantial than that, specifically with a focus on artisanal design, craft and art from the other side. The independent side that over the past decade and a half, has been the only place in the entire world were anything new of any design merit has been coming from.

That is why it is the only forum on the planet that we take an active participatory role in.

So Zero25mg, I respectfully ask that you understand that we are more about product than just about anyone in the game. Please do some more research, and then try to get to one of our exclusive authorized dealers and start touching and trying things on, then find someone who we made some clothes for 3 decades or so ago, and ask them if GBS is about product or not. At some point along the line, you will eventually realize that if you are going to talk about clothes maker and product, you are talking about us, not about them. Please don't mix us up. And please don't call us just a fashion designer. Frankly, there are far too many times these days, when that label makes me ill.

For almost 40 years, I have been making clothes for people. And on every single piece, we have had only one mission... to raise the Art and Science of making clothes by hand- to make the very best clothes that are humanly possible in today's world.

For example, let's get on to Lokihaarme's last question, and take a look at alterations and our clothes.

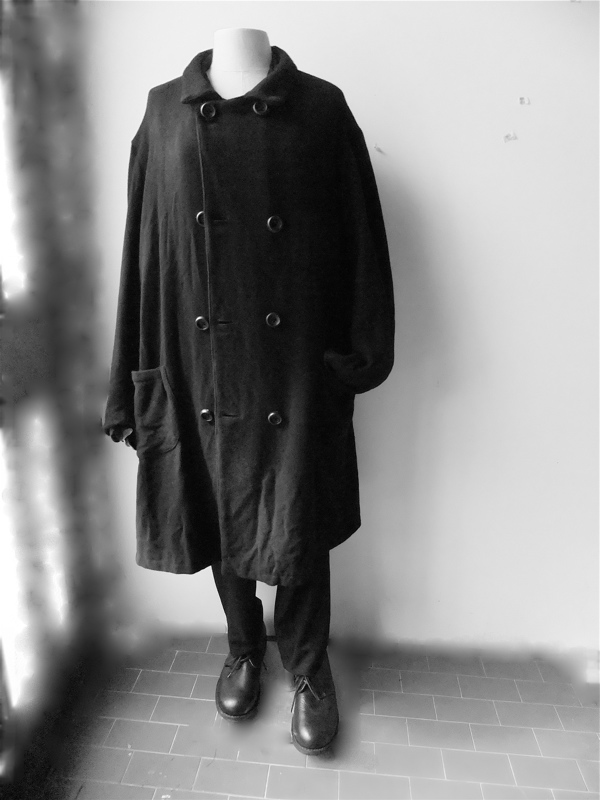

The beautiful NVJ18 Edwardian length super-jacket made for Eth0s in Shanghai was designed for

maximum performance and longevity. And that requires superb and efficient alterations capability

built-in as part of a total design concept. Our goal? : The best clothes to work on in the world bar

none when you have to repair, alter or modify them. For example, the huge extra wide seam allowances

in the center back seam that allow the jacket to be let out up to 2 sizes larger and the handsewn Ratti

pure silk side lining panels that provide easy access inside to perform other changes or repairs.

I came to Italy 16 years ago for one reason: to make the best clothes in the world, and that means alterations capability too. The new economic realities of today demand that rich or poor, every penny counts. With customers now realizing that low-prices are no guarantee of saving money in the long run, the adage of "you get what you pay for" rings more true than ever. Designers working and still producing in western industrialized countries must now really deliver... the very best money can buy.

So we have been constantly raising the bar, and setting a new level of designer label commitment. I began many years ago with an old Singer sewing machine in 1979 by making clothes one-at-a-time for friends in the attic of my parent’s home in Newton Massachussetts. Quite a few of those clothes are still worn being worn today... every few months or so, I get an email or a letter from someone telling me that they still have a piece, or a suit, that we built for them decades ago and that amazingly they can still wear it. There is some real satisfaction in that, let me tell you.

And you cannot achieve that kind of long-term design and wear performance in a garment without building adequate alterations capability into the product from the start.

So, a lot of ‘designers’ are now claiming to make handmade or ‘artisan’ clothes these days. But in fact, very few really are. Our goal is to redefine the role of real tailoring in modern clothing at the designer level. We believe the ongoing crises in the global economy are a clear symptom of an industrial system that no longer cares about customers, or human talent and skill, or people in general.

Inspite of the massive assault by corporate fashion- both cheap and luxury, to erase any form of independent human ethical and sustainable creation, production, or artistic free expression out there, we believe that now is the greatest time in the history of our race to return to the age old art of making clothes for people one-at-a-time. To rehumanizing the clothing experience to the value in our society where it properly belongs.

We believe in offering the customer a new level of service and long term value and satisfaction. So unlike anyone else in our end of the business, we guarantee our limited edition pieces made for our dealers for one year under normal use for free parts and labor repair or replacement if purchased from and handled by them. After one year, we make our repair services available at workroom rates for parts and labor. Behind the label is not just a name, but someone who made and backs up the product and will try to help to keep it working for many years. First developed for our bespoke clientele over 30 years ago. many of whom are still wearing their pieces today, this concept starts with a level of construction way beyond normal:

Interior view of a WSP08special trouser made for Arts & Science in Tokyo

fully-lined in authentic Bemberg cupro, the lining offers easy access inside for

a good tailor to make fitting alterations but also gives the owner round-the-clock

pyjama like comfort, helps maintain the drape and shape of the seat and leg,

and reduces wear and tear in the seat of the trouser. Instead of wearing out

the main fabric in the seat or some other stress point, the lining will wear out

first, at which point the linings can be replaced and the trouser can be saved for

more years of wear.

On most of our jackets, waistcoats, trousers and topcoats full interior linings in luxurious silk, Bemberg cupro, viscose or superlux cottons or linens give round-the-clock pyjama like comfort, help maintain the drape and shape of the seat and leg, and reduce wear and tear in the seat of the trouser, or other similar areas for jackets, vests and coats, adding significantly to the product's useful life. Rather than wearing out the main fabric in the seat or some other stress point, the lining will wear out first, at which point we can replace the linings and the save the garment for more years of wear.

Comment

-

-

(continued from above) "Fashion designer vs Clothes maker" + Our Views on Alterations

.

Designed to last for years: up to 2 sizes larger or smaller

In addition, the massive generous 2,5 centimeter seam allowances on all major fitting seams (almost 3 times wider than the standard production allowance in designer label clothes) on most of our jackets, waistcoats, trousers and topcoats is almost unique in the entire industry- though they cost more fabric (and at almost 200 euros a meter for example in one of our pure Alashan worsted cashmere cloth, that's not insignificant)- they allow the majority of our pieces to be altered and let out or taken in a full two sizes larger or smaller than its original cut and size.

Like almost all of our designs, this WSP08special trouser made for Arts & Science

in Tokyo in luxurious Biella double-face worsted wool, also incorporates generous

2.5 centimeter seam allowances on all major fitting seams to provide up to 2 sizing

grades of alteration capability up or down in size for extra long useful garment life.

Our experience is that people's bodies are not static. They are dynamic, they change. People get bigger and smaller over the years, most men get bigger over time. Thus, if we make a young man a pair of size 48 trousers and over the years he becomes a 50 or even a 52, the trousers can be let out to fit him, and he can still keep and use his favorite pair of trousers with all the comfort and style that were carefully built into them when they were created. That's what we call real value, and its fundamental to serious clothing. Done well, it can last you a lifetime. It's not about designing for a season or a few weeks like "fast fashion." We are designing pieces for a person over a much longer term and point of view.

Another example is this L.Parisotto silk & cotton FMJ24 waistcoat made for Journal Standard Luxe

in Tokyo. Even though it is fully lined in Bemberg cupro, you can still see the whopping 2.5 centimeter

seam allowances in the center back seam through the lining backlit by the sky behind it that give it

plenty of alterations capability.

No expense is spared at every detail:

Alterations capability is built-in to almost every design

As both tailors and designers, we fully understand the importance of making clothes not only incredibly beautiful and comfortable for their owners, but also amazingly serviceable and accessible for a competent tailor to efficiently perform repair, modification and fitting work on. We design with a tailor's needs in mind and aim for superb alterations capability from their perspective.

You can see the 2-piece waistband and double belt loops at center-back of this women's WSWP01special handmade

L.Parisotto linen & cashmere trouser made for Noodle Stories in Los Angeles. The big center-back seat seam can be

easily and quickly accessed from the inside and goes straight up through all the pattern pieces in one continuous

operation for fast, smooth and accurate waist size changes. The added pieces and construction time are significant over

a 1-piece waistband used by many designers and brands, but the long-term value and ease of alteration make all the

difference for tailors who have to work on the piece in the future. Likewise, generous hem and side seam allowances

and handsewn blindstitch work also save time and provide critical assistance for a good tailor to let legs in or out,

and take hems up or down expertly, and beautifully, with ease.

Hand sewn buttonholes, buttons and lining closures , real hand sewn taped hemlines (not machined) are easier, more straightforward and faster to take down or take out and reset by a competent alterations tailor with proper handskill training. Almost all of our trousers have 2 piece waistbands and double belt loops at center-back with quick easy open accessibility for fast, smooth and accurate waist changes. It takes twice as long for us to cut and put together the trouser assembly in this way, but if you are doing a waist alteration on the pant, it makes all the difference in the world.

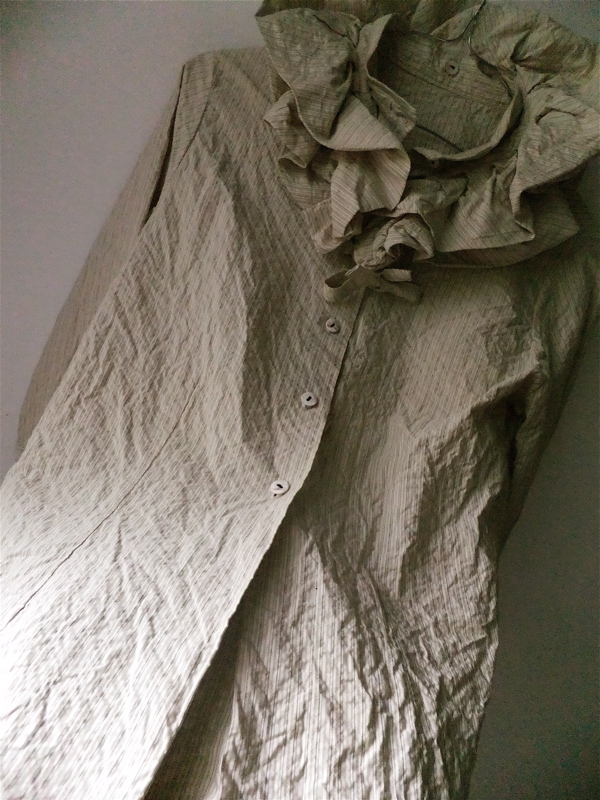

Ask any experienced tailor what part of a tailored men's shirt wears out first and inevitably he or

she will tell you it is the shirt collar around the neckline. Above, one of our 2-in-1 convertible design

FMS07 hand made shirt with detachable removable collar not only provides extra styling value with

different looks for the same piece, it also gives added protection and longer life to the collar

stand and collar pieces reducing the need to alter or replace them.

Our removable buttoned shirt collars are not only capable of providing 2-in-1 or 3-in-1 extra value with different looks for the same piece, they also give added protection and longer life to the area of a shirt that wears out the fastest. Ask any experienced tailor, nothing wears out first more than the shirt collar around the neckline area, and our removable (and replaceable) collars offer outstanding protection against this happening over time.

A hand dyed L.Parisotto Super 120's double-twist Venezia silk and cotton WSS05special shirt created for

Darklands in Berlin reveals beautifully finished french seam interior construction, which not only provides

double-seam strength and clean-finished appearance, but can also be easily opened up and made capable

of altering and modifying.

In addition, our shirts are almost exclusively sewn using beautifully finished french seam interior constructions, which not only provide double-seam strength and clean finished appearance, but can also be easily opened up and made capable of altering and changing. We also, unlike other so-called "high quality shirtmakers" do not use excessively tiny and overly-tight stitch-length sewing on our shirts like 22 stitches to the inch seams. This practice renders the piece almost impossible for a tailor to open its seams without damaging or ripping its fabric. While it may be passed off and accepted these days as a symbol of quality-factory work, we find that 'welding' a shirt together in this manner is a pointless and wasteful objective if someday we know that maybe someone will need to be able to work on it to help maintain its longevity and usefulness to its owner. A more reasonable 12-15 stitch to the inch seam when done well, is just as beautiful to look at, and for a tailor faced with repairing, modifying or fitting it, way more beautiful to work with. Ditto for all the handsewn buttons and buttonholes that we provide on all of our shirts and blouses, unlike any other designer or luxury design house.

Extra large belt loops that are not sewn on with automatic bar-tack machines as on this

pure Piacenza Alashan cashmere NNP05 trouser design made for both Eth0s in Shanghai

and Surrender in Singapore recently, are used to accommodate any width or style of belt

and have less need for replacement.

Likewise, we do not use automatic bar-tack machines for instance on pant fly's and belt loops which perform the same "welding" effect on fabrics that render them almost impossible to take out. Nor automatic buttonholers or button sewers (same effect). Extra large belt loops are used as much as possible to accommodate any width or style of belt and require less replacement. And no glue or fusing except in the most absolutely necessary instances.

Both the pure Como silk lined handmade ETC01 Piacenza cashmere coat and NNJ05 Piacenza

angora,cashmere & wool viscose lined jacket, each being made this month for Cathedral

in Osaka have secret access seams built into them that allow a good alterations tailor to

quickly get inside and out of the piece to make changes with no fuss or mess.

All of our lined handmade jackets have secret access seams built into them that allow a good tailor to quickly get inside and out of the piece with no fuss or mess so that he or she can get right to the spot that needs his or her attention be it for repair, fit adjustments or modifications and then close it right back up with no wasted time or destructive seam ripping.

Our sleeve and leg cuffs have adequate if not downright generous hem reserves inside the hems to be let down or up. On jacket surgeon sleeve cuffs, the unique handsewn buttonholes are easily opened and taken out if needed, (although we now recently set them at even higher first position for increased flexibility on hem shortening), and can be reset and resewn by a trained tailor with proper technique.

Comment

-

-

(continued from above) "Fashion designer vs Clothes maker" + Our Views on Alterations

And on our unlined tailored pieces, such as the NVJ18 (shown above earlier in this post), we use a minimum of excess construction and stitching to get in the way and clutter the interior for a tailor that needs to get inside with quick, clear and understandable access to the entire garment and the specific area or point which needs to be worked on and dealt with. Broad 2.5 centimeter seam allowances and clean taped seams with easy access for alterations are used as much as possible. The result is both clean-looking and alterations-efficient.

Hand sewn buttons and buttonholes are easier, more straightforward and faster to take

out and reset by a competent alterations tailor with proper handstitch training, especially

without using waxed thread as per our standard techniques (shown NNJ05 jacket, GJ02

pure Alashan cashmere vest, Cathedral Osaka).

To further enhance service, fit, comfort and longevity we are now starting on authorized dealer training programs where shop owners, staff and tailors can come to our workrooms at Cavarzere for beginning, intermediate and advanced training and teaching classes on how to provide better and better alterations services to customers of our pieces and our collections in their stores. We believe that full-service alterations services need to be provided to our customers at all dealer points at the retail level worldwide and are working day and night to build the training and teaching systems and infrastructure to make this a reality in the years ahead. Only in this manner, can we be able to maximize the customer's purchasing and wearing experience with our clothes and provide the most perfect fit possible with a ready to wear design piece. In an age when deskilling has reached unprecedented levels, we believe that our mission in this area is not only a smart way to further differentiate us from the competition, but also a noble and critical one to both inspire, train and employ a new generation of sartorial master craftspeople and save one of the great cultural treasures of human experience and society- making and taking care of clothes for people that really serve their needs.

And note well that all of our top GBS tailoring people over the years, including this writer, have had extensive alterations work experience. A few of our alumni have become leading alterations super-pros in their communities including major cities with lines of loyal customers, and recognize it for the noble and lucrative profession it is when done well. And there are so few competent practitioners around these days and no training or schools anywhere. So unlike most "designers" or design school programs, we do not poo-poo or avoid alterations as something too far below us to even think about or deal with. No, it is in our blood, and pervades every part of our design philosophy, business model, and teaching and training objectives. And while I will be the first to stress that no garment is perfect, and its subsequent alterations capability will always have some limitations based on a variety of factors including the specific fabric and its weave and dyeing or finishing treatments, its particular construction aspects, and its wearer's body and fitting requirements and characteristics, and the specific task requested to be performed… alterations capability in our clothes is a fundamental element of the long-term design approach that we have been spearheading for almost 4 decades.

So we design for maximum performance and longevity. And that requires superb and efficient alterations capability built-in as part of our total design concept. We do it for our customer and we do it for their tailors. And as we continue to grow and offer our world-leading services to both old and new clients in a myriad of ways, we do it for ourselves as well. After all, with our factory workroom services and backup guarantees, someday we may the ones that need to be able to get access inside our pieces and perform remedies on them as well. So we design it with our own tailoring needs in mind too, and with the constant goal of making GBS clothes the best clothes in the world- including for tailors to work on... when they have to open them up, repair, alter or modify them at some point during their long and useful lifetime.

Thank you for reading, I hope this is helpful.

Best wishes,

Geoffrey

.

Comment

-

-

NEW WORKS: ATELIER COAT & SUIT FOR ARTS & SCIENCE

.

NEW WORKS:

ATELIER COAT & SUIT FOR ARTS & SCIENCE IN TOKYO

Created this season exclusively for Arts & Science in Aoyama, Tokyo:

Handmade reproduction 1920's french atelier d-b worker's pattern coat

in hand dyed Fratelli Piacenza 1733 superfine pure fancy coating soft twill wool.

Piacenza hand dyed Super 180's "Ecstasy"14.5 micron pindot birdseye weave ultralux

wool single-breasted handmade 1910's peak-lapel silk-lined suit.

Exclusive horn button designs created by Claudio & Cinzia Fontana in Parma for GBS.

Benchmade goodyear welt-construction Concerie "800" Toscana vegetable-tanned

leather shoe, Giuseppe Rebesco for GBS.

photographed at GBS Via Spalato Workrooms, Cavarzere Venezia.

.

Comment

-

-

To Geoffrey

I appreciate you taking your time to respond to my post (Although I have been reading Sz for nearly 7 years it was my first post!!).

I am not a deep diver and to me its very pure. I like a piece of clothing if any gravity the garment has resonates with me. Whether it be silhouette,color, fabric, story, designers personality or manufacturer, etc. The most important parameters for me are 1. whether the garment will last, 2. whether it will age well or not and 3. whether it is timeless and simple (not too extravagant). I do think your clothes fit these categories and hence this is why I am very interested. PS. I don't really care if they are revolutionary or not.

Reading your post I agree I am ignorant and maybe a little irresponsible as well so I will try and enlighten myself a little more reading your posts so I can enjoy what I like even more.

Once again thanks for your time.

Comment

-

Comment